About us

We are the leading manufacturer of high-quality cutom RFID tags, to make things smarter and easier.

About Our Company

Who We Are?

We are a leading high-tech supplier specializing in RFID tags. Leveraging advanced technology and a team of seasoned professionals, we deliver precise, cost-effective solutions that meet our clients’ diverse needs. Our dedicated staff provides comprehensive support for all aspects of our products and services. We believe in fostering long-term partnerships built on mutual success, continual improvement, and shared growth.

What We Do?

We use our comprehensive industrial design and manufacturing expertise to create a wide range of high-performance, reliable RFID tags. Our product range includes RFID stickers and labels, NFC tags, on-metal RFID tags, high-temperature RFID tags, RFID seal tags, RFID laundry tags, RFID asset tracking tags, and RFID tags for inventory and livestock management. These solutions are widely used in water and electricity, medical care, laundry, security, logistics, warehousing, new retail, and industry 4.0 applications.

How We Do It?

Our experienced sales, technical support, and after-sales professionals are expert problem solvers with deep product expertise. They thoroughly understand how our custom RFID tags are manufactured, deployed, and maintained and the environments where they work best. Our sales team will recommend the most suitable products based on your application, considering materials, dimensions, shape, cost, and performance characteristics. Additionally, our technical team provides expert guidance and analyzes your application environment to ensure the chosen RFID tags deliver stable, reliable performance.

Manufacturing Process

Flip-chip encapsulation is a vital step in RFID production. In this process, the RFID chip is directly soldered onto a substrate with an antenna and then encased within a protective plastic shell. This technique offers higher integration and better performance, ensuring the stable operation of RFID tags under various conditions. The flip-chip encapsulation process can also enhance production efficiency and reduce manufacturing costs, making RFID devices more practical and economical.

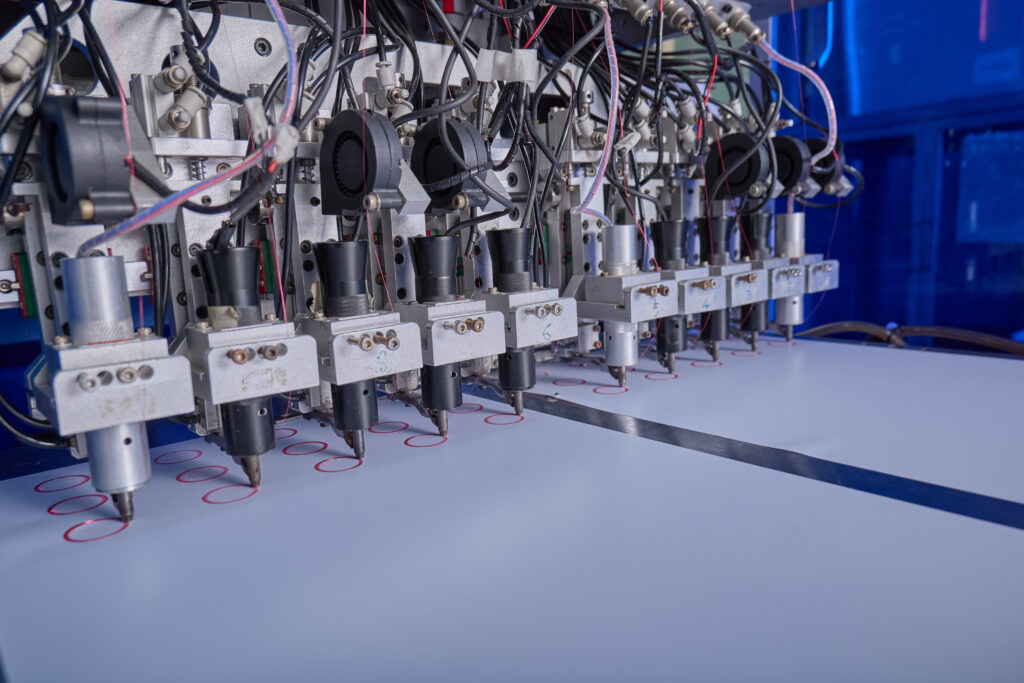

Stick Chip process is a vital component of our manufacturing chain. This phase involves precisely placing and bonding the RFID chip onto the antenna substrate, ensuring optimal signal transmission. Our skilled technicians employ advanced machinery to achieve this with remarkable accuracy. Each chip undergoes rigorous testing for quality assurance, meeting the high standards bulk purchasers and distributors set. The “Stick Chip” process is a testament to our commitment to superior quality and performance in our RFID products. Experience the difference in consistency and reliability with our meticulously crafted RFID solutions, where precision and quality are paramount.

Auto welding process: This automated process ensures optimal electrical connections between the antenna and the chip, a crucial step in RFID tag production. Our rigorous quality control measures are implemented at each stage, ensuring each weld is perfect, and our products are of the highest quality. We utilize advanced technology and skilled technicians to oversee this process, guaranteeing consistency and reliability for our bulk purchasers and distributors. Our commitment to excellence in our Auto Welding process sets us apart in the RFID industry.

We believe that “Testing” is a cornerstone of our production process. Every RFID tag undergoes rigorous testing to ensure superior performance and durability. Our comprehensive testing procedures include functionality checks, frequency testing, and stress tests under various environmental conditions. We utilize advanced testing equipment and methodologies to ensure each product meets our stringent quality standards. Our experienced technicians meticulously monitor this process, ensuring consistent quality and reliability for our bulk purchasers and distributors. This meticulous attention to detail in our testing phase underscores our commitment to delivering high-quality RFID products to the industry.

The combination is a critical step that ensures our products’ high quality and reliability. This stage involves the precise assembly of the antenna and chip, where each component is carefully combined to form the integral structure of the RFID tags. Our experienced technicians employ state-of-the-art equipment to guarantee these parts’ accurate alignment and secure attachment. This stringent process is closely monitored and subjected to rigorous quality checks, ensuring that each product we produce meets the highest performance and durability standards. Our commitment to excellence in this crucial manufacturing phase sets us apart, making us the go-to choice for bulk buyers and distributors seeking top-notch RFID solutions.

The inlay Lamination phase is pivotal in ensuring the durability and longevity of our RFID tags. During Inlay Lamination, the assembled RFID inlay is encapsulated between layers of durable material, providing protection and enhancing the product’s overall stability. Our advanced lamination techniques and equipment ensure a seamless, secure encapsulation, preserving the integral components from environmental factors. Rigorous quality checks are conducted throughout this process, maintaining our commitment to delivering high-quality, robust RFID solutions. This dedication to excellence in our manufacturing process is why bulk buyers and distributors entrust us with their RFID requirements.

The Shengyuan Difference in Computer Privacy Screens

At Shengyuan, we don’t just cut film to size. We combine material science, precision engineering, and stable production to deliver privacy screen filters that are easy to deploy and easy to trust.

Optical Material Expertise

We develop and select optical films with controlled privacy angles (28°/30 °), clear front viewing, and stable contrast, so users can work normally while side views are blocked.

Full Product Chain & Customization

From acrylic hanging panels and PET privacy films to AR dual-explosion-proof coatings, we offer a complete product chain and custom cutting for oversized monitors, TVs, and special screens.

Proven Device Compatibility

Our privacy screens are tested on mainstream brands such as HP, Dell, Lenovo, and MacBook, helping IT teams roll out standard SKUs across different device fleets.

ISO9001 Quality & Compliance

Production runs under an ISO 9001-certified quality system, with RoHS/REACH-compliant materials, ensuring stable performance and documents ready for audits and vendor approval.

Scalable Capacity & On-Time Delivery

Advanced coating, laminating, and precision-cutting lines support both pilot orders and large rollouts, with clear lead times and shipment plans for each project.

OEM / ODM & Branding Support

We support OEM / ODM, custom sizes, labeling, and packaging, helping IT resellers, brands, and distributors build their own privacy screen product lines.

How We Help You Protect On-Screen Data

We treat every project as a rollout, not just a one-time shipment. Our process is designed to make device mapping, sampling, and deployment simple for your team.

Step 1 – Understand Your Devices and Use Cases

You share your device list, screen sizes, and key scenarios such as offices, branches, hospitals, or mobile workers. We listen first and clarify what needs to be protected.

Step 2 – Recommend the Right Privacy Screen Solutions

Based on your devices and budget, we propose matching privacy screen families, mounting types, and privacy angles so each user group gets a practical solution.

Step 3 – Sampling and Pilot Testing

We provide standard samples for quick size checking and custom-cut samples for key devices. Your team can test fit, clarity, and user acceptance before full rollout.

Step 4 – Size Mapping and Rollout Planning

Together, we confirm final sizes, SKUs, and quantities for each location. We then prepare a clear production and shipping plan that fits your project timeline.

Step 5 – Mass Production and Global Shipping

Our ISO 9001-managed lines produce your order with consistent quality checks. We support flexible shipping options for samples and bulk goods to different regions.

Step 6 – Ongoing Support and Optimization

After deployment, we stay available for feedback, re-orders, new device models, and continuous optimization of your privacy screen portfolio.